The most important factor in selecting a thermistor is to identify the temperature range in which it will be used. SEMITEC thermistors (sensor core elements) are available for a variety of temperature ranges to support various applications.

Figure 1 shows a list of thermistor types in terms of temperature range.

Select a thermistor that matches the temperature environment it will be used in.

Figure 1 List of NTC Thermistor Types

- Thin-Film Thermistor

- Ultra High Precision Thermistor

- High Precision Thermistor

- Thin Thermistor

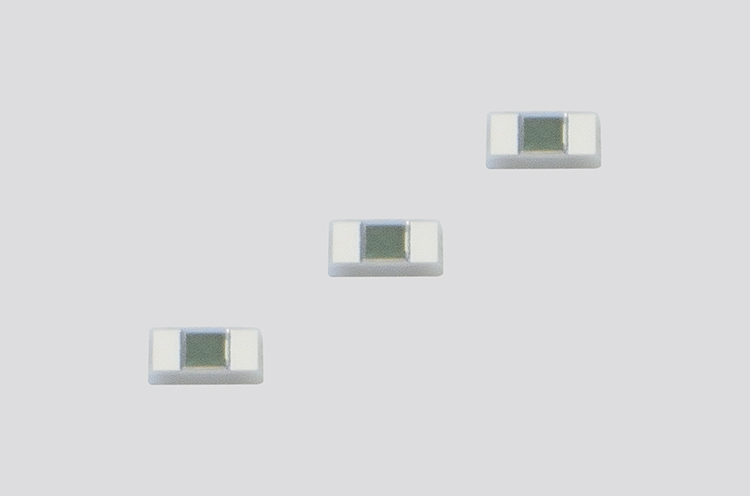

- Surface Mount Thermistor

- High Heat Resistance Thermistor

Next, select a shape appropriate for the environment and installation to be used.

Figure 2 shows a list of thermistor types in terms of shape.

SEMITEC’s thermistors are broadly classified into chip and thin film by manufacturing method.

Chips are produced through the sintering of thermistors using ceramic sintering technology, resulting in a sintered body that is subsequently diced.

The thin film is a thermistor thin film formed on a ceramic substrate using thin film creation technology from semiconductor manufacturing technology. (This is SEMITEC’s proprietary technology)

The thermistor element is sealed with glass or resin depending on the operating environment, such as heat resistance.

In addition, surface mount and radial thermistors that are mounted on a substrate , radial and axial thermistors that are suitable for the environment in which they are mounted and for being processed into thermistor sensors are also available.

Please refer to the Thermistor Sensor Catalog for the shapes of thermistor sensors.